Posted in Case Studies on June 16th, 2015

Picture this

You are a multi-site manufacturing company that has grown organically and by acquisition over many years. Your products are installed throughout the UK and beyond. You have a responsibility to maintain them for perhaps ten years or more. You may even refurbish used equipment to extend its life beyond that. You are operating in national and international economies that may be growing by just one or two percentage points. How can you maintain or increase profit margins in these circumstances?

Well, for one thing, you’ll have to pay close attention to your costs. You’ll probably have already made progress by investing heavily in IT solutions such as Electronic Data Management to improve efficiency and reduce the cost of creating, distributing, archiving and retrieving the commercial A4 paper documents used in your business.

The good news is that you can now get even more out of that investment by including your large format documents in the system, making them available to all who need them, when they need them, saving money at the same time as improving speed of access and quality of service: what’s known as a ‘win-win’ situation.

One internationally renowned company who prefers to remain anonymous, has done exactly that, by installing a Colortrac* large format scanner. You can be sure that this approach really does work. Seeing is believing.

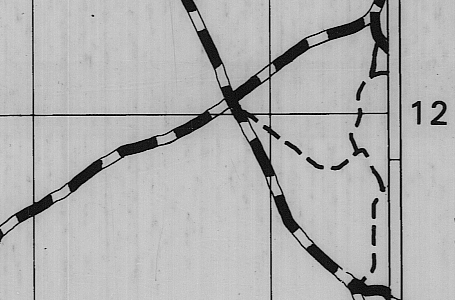

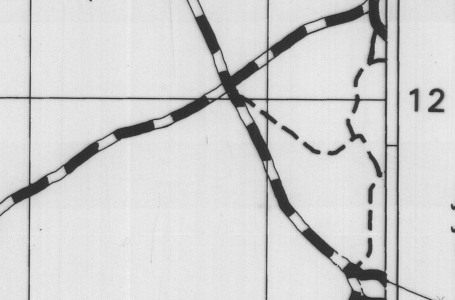

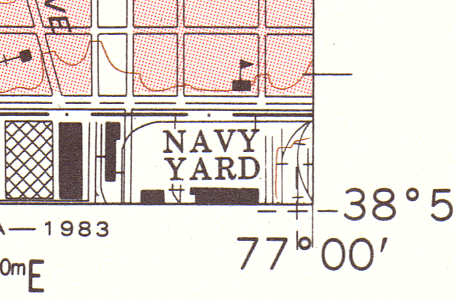

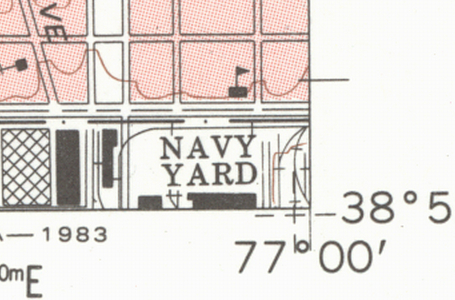

The company’s Archives department has to safeguard the company’s records for all its locations. This is no easy task, since the company’s main site covers over 40 acres and houses over 500 staff in a large number of buildings. The records include all contracts, HR documents, credit management documents and computer archives. The department also looks after plant, facility and estate drawings as well as all legacy engineering and product documentation. These records are valuable items and the company cannot afford to take any risks. The main archive alone comprises 50 storage bays, each of which hold 384 boxes of A4 documents. The archive would be even bigger had the company not installed a Electronic Document Management (EDM) system. Since that date, all new documents in the organisation, including engineering drawings, have been or are being created electronically and are accessible on line to appropriately authorised users anywhere through the EDM system.

Expensive floor space

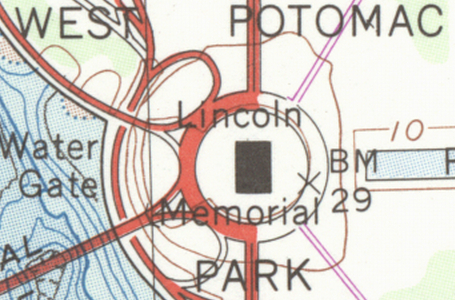

The company’s drawing archive occupies a significant amount of expensive floor space. The departmental manager comments, “We have all the mechanical, electrical, PCB and electronic drawings for all the equipment we’ve ever produced. We have to provide access to them because there are many of our earlier products in operation around the world. We can get requests for any of the drawings for them, at any time.” He adds, “We pay for the storage space out of our budget at a cost of almost £25,000 each year. It is also very time consuming to retrieve, copy and issue the paper drawings on demand and the condition of the originals deteriorates with handling.” In addition, he points out, “Our facilities department has over 7,000 drawings: site plans, building drawings and electrical, water and telecommunications drawings. For insurance reasons at least, these drawings have to be kept in perpetuity.”

Scanning bureau not economic

The Archive department knew that by capturing these drawings electronically and making them available through the company’s EDM system, they could make a contribution to cost reduction without an associated reduction in the level of service they provided. Some years ago, the department looked at using an external scanning bureau to handle the complete task, but the cost of this approach was uneconomic. More recently, consideration was given to carrying out the work inhouse. This way, control would be local and the task could be interlaced with the existing workload. In addition, at the end of the project, the company would retain an inhouse facility for capturing any other large format documents for electronic storage and distribution.

Know-how and experience

The Archive manager recalls, “We spoke to an independent dealer who recommended the Colortrac range of scanners. We were told that they had the know-how and experience of large format A0 scanning that we required.” He continues, “They arranged an on site demonstration of a Colortrac large format scanner. We really put it through its paces. We used the worst documents we could find. Some were so faded that it was almost impossible to see what they were. We tried it with dyelines, negatives, positives, microfiches – everything.”

The Department’s proposal was accepted and the scanner was installed. The Archive manager points out, “The solution was perfect for the facilities drawings, too. All we needed to do initially was to scan the drawing and make them available to our facilities management people. We didn’t integrate them with the archive system because we were going to outsource the responsibility for the facilities management of our UK estate, although we could have easily done so.”

Seamless integration

According to the manager, “The whole experience was excellent. The dealer installed the scanner, set it up, provided a tutorial and that was it. The software was so easy to use because things were so user friendly.” For best productivity, a highly automated system was required. There was a need to create a process to scan A0 and A1 drawings in batches, automatically index and register them with the EDM system, storing them in the CD jukebox. The Archive manager reports, “I’m an administrator. I’m non-technical and I’m not an IT person, either. But I was able to create a program to zone the title box on the scanned engineering drawings, interpret the contents and then index them on date, title and drawing number. I just press a button and feed in the drawings. Each A0 drawing takes less than three minutes from start to finish, including scanning, indexing and registering into the EDM system. The integration is seamless.”

Well worth the money

The capture of the facilities drawings is progressing well. The manager reports “We’ve scanned over 2,000 large format drawings already. We use Colortrac’s software to clean them up automatically as we scan them, and we are on target to complete the work by July.” Have any of the expected benefits been realised yet? The manager concludes, “I won’t be able to say exactly how much money we’ve saved until the job is completed. But the scanner is brilliant; it really does the job. As we are emptying the plan chests of drawings, we formally release the space, taking it off our budget. So it has been well worth the money already.”

* For all current models see our Large Format Scanner Overview.